Stop Solving the Same Problem Twice.

When failure becomes routine, you stop asking why. That’s the Zombie Myth – The myth that never dies.

Book a 20-Minute Review

When failure becomes routine, you stop asking why. That’s the Zombie Myth – The myth that never dies.

Book a 20-Minute Review

Across mining operations, we’ve found a common pattern: repeated failures, misdiagnosed issues, and parts replaced without root cause investigation.

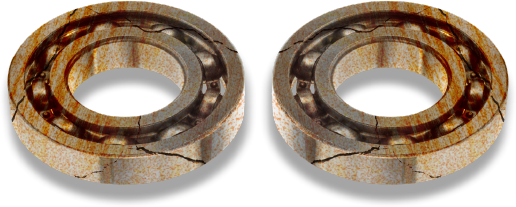

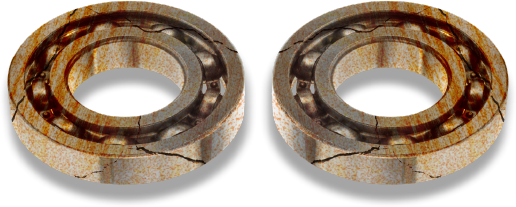

In many cases, bearings are failing prematurely, not because of poor manufacturing, but because of overlooked systemic problems:

Our field engineers have supported sites dealing with breakdowns on conveyor pulleys, fans, motors, gearboxes, crushers, and more.

If you’ve ever felt like your failure reports don’t go anywhere, or you’ve replaced the same part too many times, you’re not the problem. The system is.

There’s a belief embedded in too many maintenance plans:

– Bearings just wear out.

– Failures are inevitable.

– This is just how it is.

Zombie Myth: the industry autopilot where failures are accepted, replacements are routine, and the root cause is ignored.

It shows up as:

This mindset isn’t malicious. It’s momentum.

But here’s the truth: bearings don’t just fail. Misalignment, improper sealing, contamination, and poor bearing selection are signs of deeper system issues.

The Zombie Myth thrives when we stop questioning those signals.

DASH Engineering kills the myth with root-cause clarity.

At DASH Engineering, we believe failure is not the end; it’s the opportunity to engineer something better. We don’t stop at the diagnosis. We design the fix.

We deliver:

You don’t need more parts. You need fewer shutdowns.

You don’t need better band-aids. You need the truth behind the breakdown. That’s what we offer: with field credibility, engineering clarity, and long-term results.

We work with some of the most respected mining operations across Australia. These are teams that were tired of replacing parts and ready to engineer solutions that last.

Book a 20-minute review to stop repeating failures and build reliability.

Here’s what you get:

"*" indicates required fields